Smarter Inventory Management: Reduce Waste and Maximise Profit

In Singapore’s competitive market, effective inventory management is crucial to control costs and protect profits. This guide shows how modern POS systems can turn stock management into a powerful business advantage.

This comprehensive guide will walk you through actionable strategies to transform your inventory management from a constant headache into a competitive advantage, with practical examples of how modern Point-of-Sale (POS) systems can streamline the entire process.

The Real Cost of Poor Inventory Management

Before diving into solutions, let's understand what's at stake. SMEs face multiple challenges including rising operational costs, cash flow constraints affecting 51% of businesses, and the reality that 3 in 5 saw revenue declines during recent economic disruptions. Poor inventory management compounds these issues in several ways:

Hidden Costs

- Dead stock accumulation: Products that expire or become obsolete tie up valuable capital

- Emergency restocking costs: Rush orders to avoid stockouts often come with premium pricing or suboptimal quantity

- Storage inefficiencies: Space optimisation is one of the biggest challenges SMEs face, particularly in Singapore where rental costs are among the highest in Southeast Asia

- Labour costs: Manual counting and reconciliation consume hours of staff time weekly

These problems can have compounding effects, leading to lost sales from stockouts during peak periods, damaged reputation when popular items are consistently unavailable, and reduced customer loyalty as shoppers turn to competitors.

Understanding Modern Inventory Forecasting

Successful inventory management starts with accurate forecasting. Effective inventory management involves active monitoring of stocks, the use of technology to forecast demand, and a smart strategy for replenishing stocks as demand changes. Here's how to implement practical forecasting methods:

1. Start with Historical Data Analysis

Time-series forecasting analyses past sales data to predict future trends, helping businesses identify long-term patterns and seasonal variations. Even small businesses can benefit from this approach:

Weekly Pattern Recognition

- Track your best and worst selling days

- Identify lunch rush patterns for F&B businesses

- Note weekend versus weekday variations

Seasonal Trend Mapping

- Track sales spikes during festive periods (Chinese New Year, Hari Raya, Deepavali)

- Monitor effects of school holidays or weather changes

2. Automate Your In-Store Analytics

ABC inventory analysis ranks products from A to C based on their financial importance to the business, with "class A" items being the most valuable in terms of sales, risk, demand, and cost. Here's how to implement it:

| Category | % of Items | % of Revenue | Recommended Action |

| A (Top 20%) | 20% | 80% | Check stock daily, maintain safety stock, and set automatic reorder alerts. |

| B (Middle 30%) | 30% | 15% | Review weekly, maintain moderate safety stock, and sustain regular supplier relationships. |

| C (Lower 50%) | 50% | 5% | Review monthly, keep minimal stock, and consider discontinuing slow movers. |

3. Calculate Your Optimal Reorder Points

Economic order quantity (EOQ) is the ideal order quantity during regular times, calculated using formulas that consider ordering costs, holding costs, and demand rates. While the full EOQ formula can be complex, here's a simplified approach:

Basic Reorder Point Formula: Reorder Point = (Average Daily Sales × Lead Time) + Safety Stock

Example for a Popular Product:

- Average daily sales: 10 units

- Supplier lead time: 5 days

- Safety stock: 20 units

- Reorder point: (10 × 5) + 20 = 70 units

When stock hits 70 units, it's time to reorder.

Leveraging Technology: How EPOS Transforms Inventory Management

As businesses grow, manual inventory management becomes unsustainable. SMEs still handling receiving, storing, and shipping goods, can suffer from preventable mistakes and inefficiencies. Modern cloud-based POS systems address these challenges through automation and integration.

Real-Time Stock Tracking

EPOS's inventory management system provides immediate visibility into your stock levels across all locations. The system notifies owners when stocks are low in quantity and automatically updates stock count when a sale or purchase order is made. This real-time tracking eliminates the guesswork and manual counting that consume valuable time.

Automated Reordering and Forecasting

EPOS has forecast tools that help generate and send purchase orders based on lead time, sales trend and on-hand quantity. This automation means:

- No more emergency orders due to forgotten restocking

- Optimal order quantities based on actual sales data

- Reduced holding costs from over-ordering

Multi-Channel Integration

With omnichannel integration, inventory updates in real-time across all sales channels. When someone buys from your online store, the inventory automatically updates in your physical store and other connected platforms. This unified approach prevents overselling and ensures accurate stock visibility.

Comprehensive Reporting and Analytics

The EPOS POS system generates detailed reports that reveal:

- Fast-moving versus slow-moving inventory

- Seasonal demand patterns

- Profit margins by product category

- Supplier performance metrics

These insights enable data-driven decisions about which products to stock, when to run promotions, and how to optimise your product mix.

Practical Implementation Strategies

Here’s how to put smarter inventory management into practice:

Step 1: Conduct a Comprehensive Stock Audit

Before implementing any new system, establish your baseline:

- Physical count: Verify actual quantities against records

- Identify discrepancies: Document gaps between systems and reality

- Categorise dead stock: Mark items for clearance or disposal

- Review storage: Optimise layout for efficiency

Step 2: Establish Clear Processes

Create standard operating procedures for:

- Receiving goods: Check quantities and quality upon delivery

- Stock movements: Document transfers between locations

- Cycle counting: Regular spot checks rather than annual counts

- Returns processing: Handle customer returns systematically

Step 3: Set Up Smart Alerts

Configure your POS system to notify you when:

- Stock levels hit reorder points

- Products approach expiry dates

- Slow-moving items exceed holding periods

- Unusual sales patterns occur

Step 4: Train Your Team

Ensure all staff understand:

- How to use the POS system for stock management

- Importance of accurate data entry

- Proper receiving and storage procedures

- How to identify and report discrepancies

Cost-Benefit Analysis: Making the Investment Work

Understanding Government Support

With SME grants covering 50% to 80% of costs, Singaporean businesses can adopt business command centres that manage payments, inventory, customer data, loyalty programmes, and real-time analytics. The Productivity Solutions Grant (PSG) makes advanced inventory management accessible even for small businesses.

Calculating ROI

Consider these tangible benefits:

- Reduced dead stock: Save 10-15% of inventory costs

- Fewer stockouts: Capture 5-8% more sales

- Labour savings: Reduce inventory management time by 60%

- Better cash flow: Free up 20% of working capital

For a business with S$500,000 annual revenue, these improvements could add S$40,000-60,000 to the bottom line.

Overcoming Common Implementation Challenges

Challenge 1: Staff Resistance to New Tech

- Start small — pilot in one category or outlet

- Celebrate early wins

- Conduct hands-on training sessions

- Appoint tech-savvy “champions” internally

Challenge 2: Data Migration Concerns

- Begin with fresh inventory counts

- Run old and new systems in parallel for a month

- Verify data accuracy before switching fully

- Keep backups initially

Challenge 3: Integration with Existing Systems

- Choose systems with proven integration capability

- Test connections with accounting or CRM tools

- Work with vendors offering local support

Looking Ahead: Future-Proofing Your Inventory Strategy

Machine learning has revolutionised inventory management for Singapore's retailers by enabling unprecedented accuracy in demand prediction. As technology continues to evolve, businesses that embrace smart inventory management will gain significant competitive advantages.

Emerging Trends to Watch

AI-Powered Forecasting: Advanced algorithms that consider social media trends, weather patterns, and economic indicators for more accurate predictions.

IoT Integration: Smart shelves and RFID tags for automatic stock counting and real-time tracking.

Predictive Analytics: Systems that anticipate customer needs before they arise, enabling proactive inventory positioning.

Taking Action: Your Next Steps

- Assess your current situation: Calculate your inventory turnover ratio and identify your biggest pain points

- Explore technology options: Research POS systems from providers like EPOS that offer comprehensive inventory management features

- Check grant eligibility: Singapore SMEs registered and operating locally can get sizeable 50% grants under the Productivity Solutions Grant

- Start small: Implement changes gradually, beginning with your most important product categories

- Monitor and adjust: Track key metrics and refine your approach based on results.

Making Inventory Work Smarter, Not Harder

Smarter inventory management isn't just about having the right products at the right time—it's about transforming your entire approach to stock control. By combining proven forecasting methods with modern technology, Singapore SMEs can reduce waste, improve cash flow, and maximise profitability.

The investment in proper inventory management pays for itself through reduced dead stock, fewer emergency orders, and increased sales from better availability. With government grants available to offset costs, there's never been a better time to upgrade your inventory management capabilities.

Start with one small improvement today—whether it's implementing ABC analysis or setting up your first automatic reorder point. Each step forward brings you closer to an optimised, profitable inventory system that supports your business growth ambitions.

Related Articles

Boosting Supplier Resilience: A Practical Guide for Small Businesses in Singapore

Strong supplier relationships are vital for smooth operations and healthy profit margins. Learn how effective supplier management can help small retailers and F&B businesses in Singapore ensure consistency, quality, and growth.

Delegation for Founders: Avoiding Burnout in F&B and Retail

Founders are driven and resilient, but even the toughest can face burnout. Learn why entrepreneurs are vulnerable, how to spot the signs early, and what steps can help restore balance and focus.

3 Restaurant Tasks You Can Automate Today

Running a restaurant in Singapore means juggling many moving parts amid rising costs and competition. Automation can ease the load—boosting efficiency, cutting costs, and letting staff focus on what matters most.

Accelerate Your Business

All-in Business 5G+ SIM Only Plan

Made Easy and Secure

Keep connected to your business in SG and overseas securely with roaming data & mobile protect.

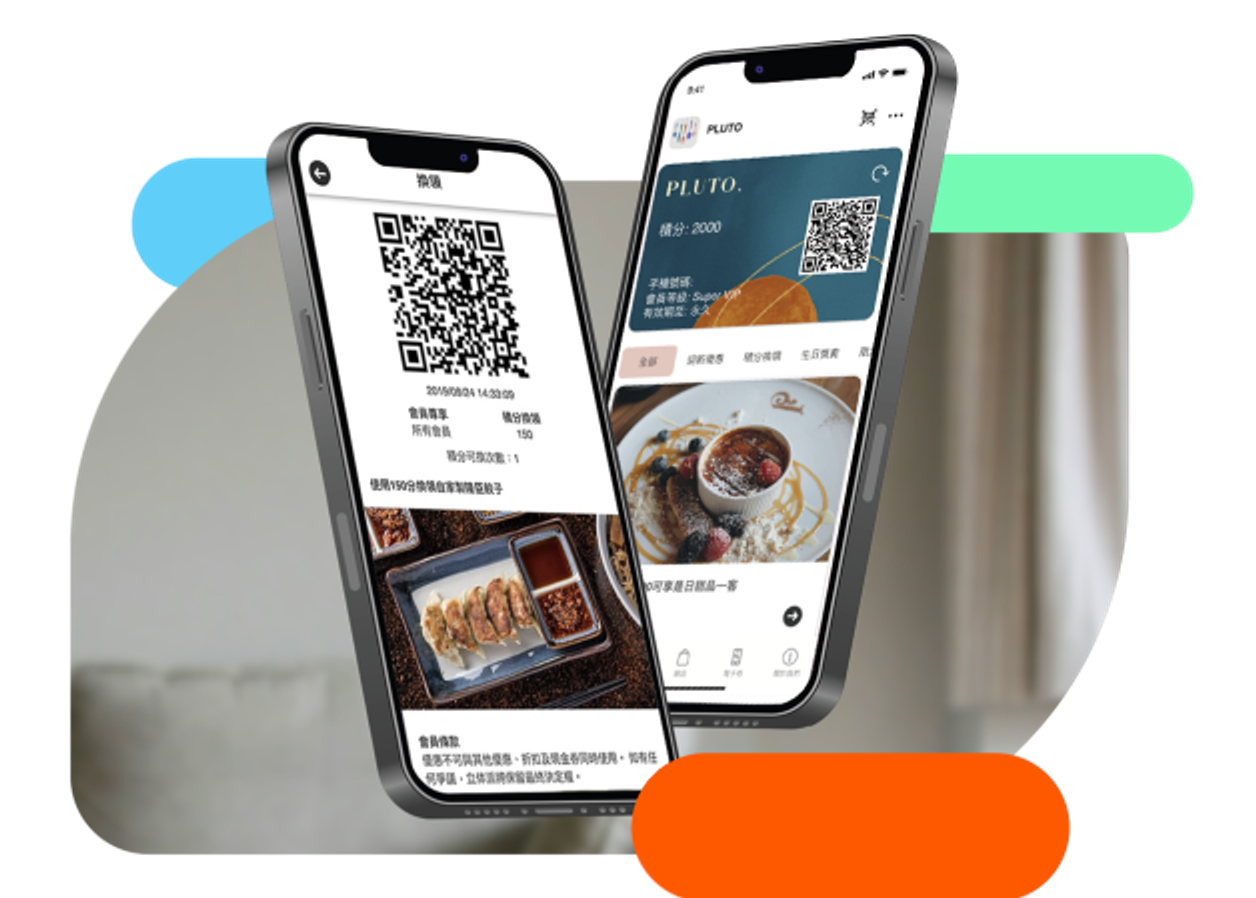

Customer Engagement

Made Easy

Engage and identify your best and most profitable customers to boost retention.

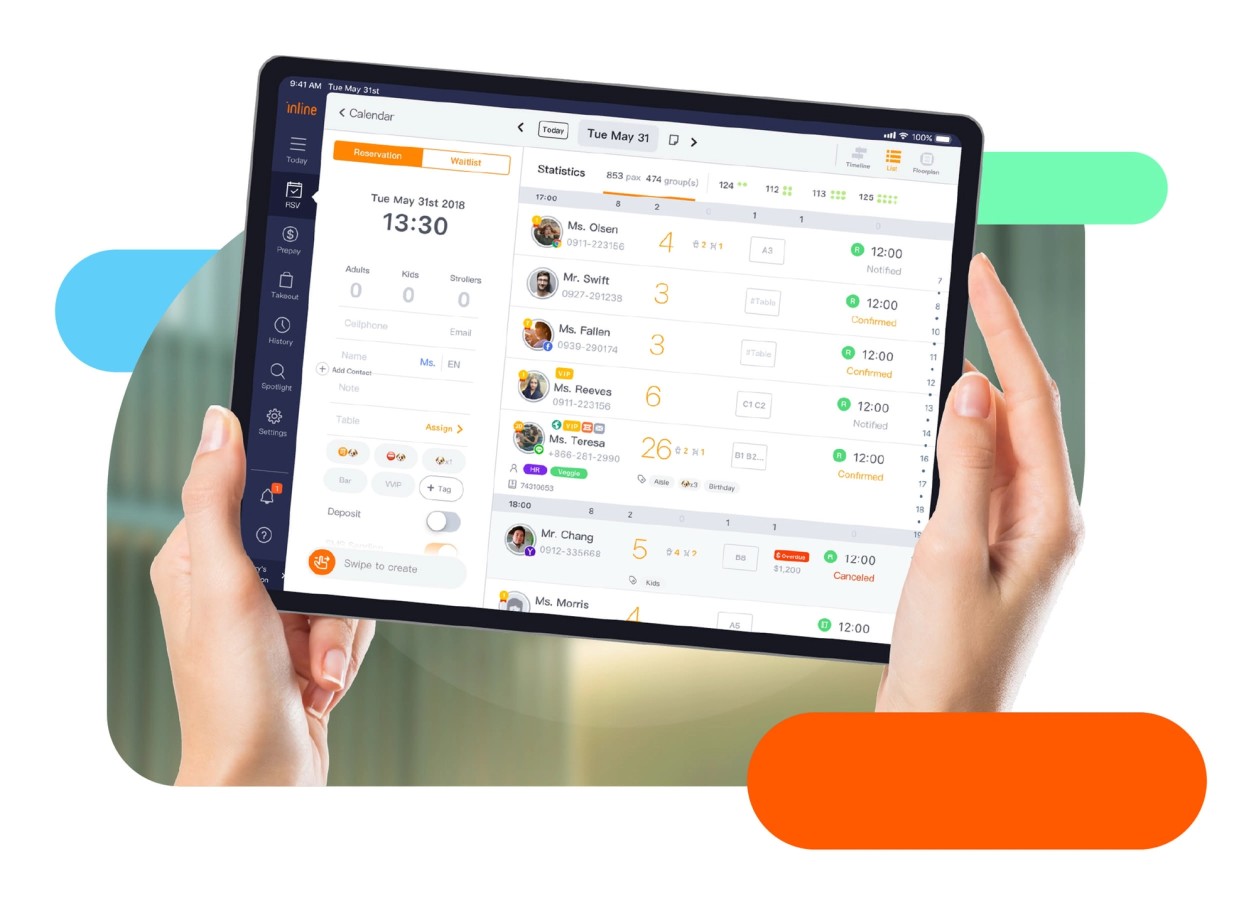

Table Management

Made Easy

From first click to final bill, manage bookings, tables, and guests with ease.